Nickel alloy is an alloy based on nickel and added with other elements. The Monel alloy containing about 30% copper, produced around 1905, is an earlier nickel alloy. Nickel has good mechanical, physical and chemical properties. Adding appropriate elements can improve its oxidation resistance, corrosion resistance, high temperature strength and improve certain physical properties. Nickel alloys can be used as materials for electron tubes, precision alloys (magnetic alloys, precision resistance alloys, electrothermal alloys, etc.),

The Inconel 600 and 625 alloys show exceptional resistance to oxidation, stress-corrosion cracking, and many acids and alkalis. Perfect for aggressive and high-temperature environments.

These alloys maintain their structural integrity and strength even in temperatures up to 1000°C, making them suitable for the most demanding applications.

Nickel alloy plates can be easily formed and welded without compromising structural properties, which reduces manufacturing time and costs.

With high strength-to-weight ratio and resistance to fatigue and thermal shock, our plates ensure long service life even in dynamic conditions.

Over 10 years in the international steel and alloy export market

Integrated industry and trade services ensuring complete supply chain support

Rapid delivery with large stock availability

OEM/ODM services available

24/7 customer service

Dedicated QA/QC team for quality assurance

Free samples and third-party inspections supported

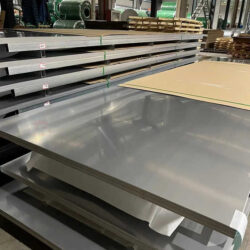

| Product Name | Nickel Alloy Plate Sheet |

|---|---|

| Material Grades | Inconel 600, Inconel 625, Monel 400, Hastelloy C276, Nimonic 75/80A |

| Nickel Content (Min) | 65% |

| Elongation (≥%) | 20% |

| Ultimate Strength (≥ MPa) | 965 MPa |

| Resistance | 1.15 μΩ·m |

| Thickness | 0.8–36 mm or customized |

| Width | 650–2000 mm or customized |

| Length | 0.8–6 m or customized |

| Surface Finish | Bright, Polished, Pickled, Sandblasted, etc. |

Nickel-Based High-Temperature Alloys: With elements like Cr, Mo, Co, Al, Ti for use at 650–1000°C

Nickel-Based Corrosion-Resistant Alloys: Suitable for acid and stress corrosion

Nickel-Based Wear-Resistant Alloys: For applications requiring durability and abrasion resistance

Logo Printing: Available (Min. 100 kg)

Custom Packaging: Available (Min. 100 kg)

Graphic Customization: Available (Min. 100 kg)

MOQ: 1000 KG

Sample: Free samples available

Packaging: Standard seaworthy packaging

Lead Time:

1–100000 kg: ~31 days

100000 kg: Negotiable

Delivery Terms: EXW, FOB, CIF, DDP, etc.

Payment Methods: T/T, L/C, Western Union, MoneyGram, etc.

High-quality Prepainted Galvanized Steel Coil, durable Roofing Sheet solutions, or reliable Stainless Steel Series and Steel and Alloy products, PPGISteelCoil.com is your trusted partner. With over 20 years of experience, we specialize in exporting premium OEM steel materials to Europe, the US, Japan, Australia, and India. Our wide range of offerings includes customized Roofing Sheet, precision-engineered Stainless Steel Series, and a full suite of Steel and Alloy components. Our customization services and fast 25-day delivery ensure that every client receives precisely what they need, on time.

PPGISteelCoil.com has earned a strong reputation for consistency, quality, and global reliability. Whether you’re sourcing Prepainted Galvanized Steel Coil for industrial manufacturing, Roofing Sheet materials for modern construction, or top-tier Steel and Alloy and Stainless Steel Series solutions for specialized applications, our expert team delivers tailored results backed by decades of expertise and an unwavering commitment to excellence.